Faro Vantage E

is a portable instrument that allows fast and precise on site measurements reducing the inspection times.

3D measurements

The laser tracker measures two angles (zenith e azimuth) using built-in encoders and one distance by mean of an absolute laser beam

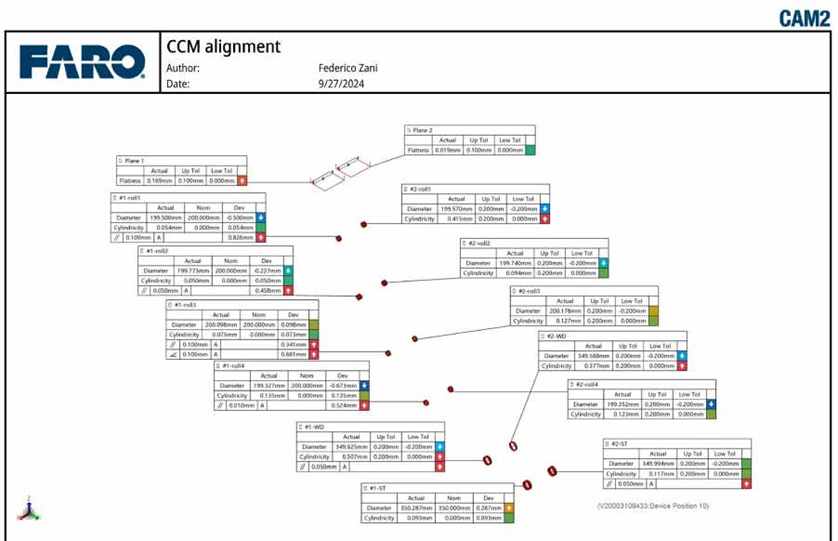

3D software package

Faro's CAM2 software allows fast, precise and efficient measurements

Integration

Real time measurements, flexibility / fast response / precision, automatic generation of reports

3D measurements

measurements of complex entities (planes, pins, slots, holes, lines, tubes, ...)

Quality control

check piece vs. nominal dimensions

Manufacturing inspection

speed up geometrical tolerances verification

Machine installation

assure proper and precise assembly of machines or components

Alignment survey

check of actual alignment status for stands, machines, ...

Services

3D Inspections

3D measurements on assembled parts (even of large size)

Alignments

Alignment survey of Continuous Casting Machines

Quality control of manufactured pieces

Comparing actual dimensions with CAD model

Machines installation

Levelling to gravity with high precision

Contacts

Location:

via Poscolle 8C, 33100 Udine - Italy

Email:

Call: